Cottonseed Oil Production Line

Cottonseed process production line provided capacity:10-500TPD

Capacity:

Cottonseed oil content is 16%-27%. For cottonseed, our company supply mechanical pressing line and solvent extraction process line according to customer production capacity.

Pre-treatment and Pre-press

Cottenseed → Metering→Winnowing → Husking→Flaking→Cooking→Pressing→Cake

Shelling

The shell of cottonseed is very solid, removing the shell is the first step before extracting oil protein. The shell of cottonseed can be used to produce furfural and cultured mushrooms. we use the equipments comprised of shelling,magnetic separation,crushing to remove the shell of cottonseed.It helps greatly increase the oil yield.

Kernel husk separator

It is mixture after shelling of cotten seed.The mixture includes full oil seed without any crushing,seed shelled and husk,all the mixture must be separated.

Flaking

Flaking means a certainty granularity of soy lamella was prepared for flaked of about 0.3mm, the oil of raw material can be extracted in the shortest time and maximum, and residual oil was less than 1%.

Cooking

This process is heating and cooking for rapeseed which is easy to separate of oil and can provide the oil quantity from prepress machine.It is easy to operate and have long life.

Mechanical Pressing Line

Our company screw oil press is big scale continuous press equipment, pass ISO9001-2000 quality certification, can produce cottonseed, rapeseed, caster seed, sunflower, peanut and so on. It’s feature is capacity is big, power consumption small, running cost low, low residual oil.

Solvent Extraction Process

According to solvent extraction, can get high oil yield. Big volume extractor design, high process capacity, high benefit and low cost. Special solvent vapor recycling system, keep clean production environment and high efficiency. Energy reusing and low energy consumption.

Successful Cases

-

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

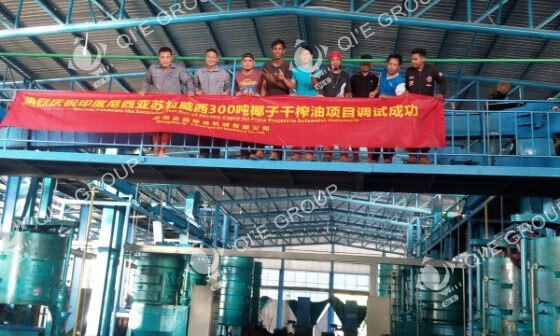

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

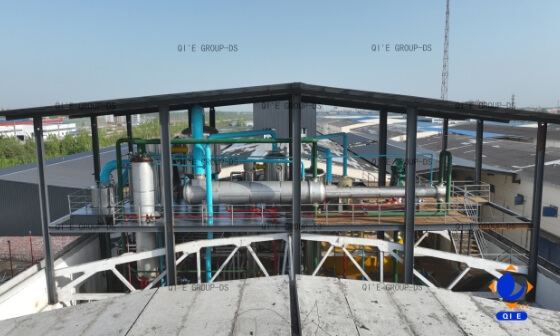

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

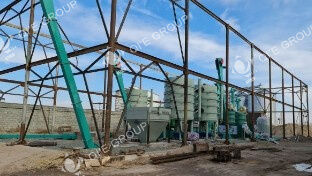

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language